ATA Case Foam Inserts

While an ATA case is rugged enough to withstand a minimum of 100 shipments, it is the foam inside the case that prevents your equipment from getting damaged. We create custom foam inserts for ATA cases that are specifically cut to safely cushion your fragile components. A FUSH Cases’ custom cut ensures a precise fit that provides optimal shock absorption and protection from impact. The customized case cavities also keep your items neatly organized for easy access and packing, as well as showcase them for sales presentations.

The Right Foam

Not all foams are created equal. The best protection requires using the best foam for your items.

-

Polyethylene Foam. A “go-to” foam for most carrying case insert projects, polyethylene provides outstanding cushioning, vibration dampening and shock absorption. It is non-abrasive, dust-free, and chemical and water resistant.

-

Cross Linked Polyethylene Foam. Because it is strong, shock absorbing, and impervious to mildew/mold/rot/bacteria, Cross Linked Polyethylene Foam is a superior packing material. It resists chemicals, is nontoxic, and contains no CFCs, HCFCs, or hydrocarbon blowing agents.

-

Polyurethane Foam. A top choice for consumer products and fragile items, polyurethane is lightweight, shock absorbing, and abrasion/ mildew resistant.

Our experienced foam fabricators will select the right foam for your project. Your items’ composition, weight, and fragility are all factors used to determine proper foam type and density.

The Right Fit

FUSH Cases design experts will create a fully-custom insert precisely cut for your items. While it is best to work with the actual items, we can also work from DXF files, computer drawings and specs, photos, or sketches with measurements. Once the design is complete, we utilize our state-of-the-art cutting machines to cut the foam. With this advanced technology, we can cut the most intricate details as well as multiple cavity depths to accommodate items of varying sizes – quickly and cost-effectively.

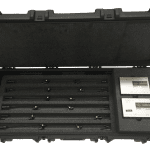

Example of a Customized ATA Case Foam Insert

We were tasked with creating multiple custom ATA case foam inserts to house an industrial gas collection system for highly sensitive analysis of gas through-put and composition. The client, which ships this fragile system to Europe twice a year for recalibration and maintenance, as well as extensively transports it for use out in the field, was experiencing substantial damage during travel. Packaging it with spray foam in a double wall corrugated carton was not affording sufficient protection.

After considering the case components and the client’s transport needs, we determined 1.7 pound density black polyethylene foam was the ideal foam for the project. Working with the system itself, which the client provided, we designed and cut a custom foam insert for the ATA case (which was also provided by the client). The design included custom foam in the case lid to adequately protect the highly sensitive piece of testing equipment.

If you need a custom foam insert for your ATA case, give us a call. As a full-service foam fabricator with a large selection of foam in stock, we offer very short lead times.